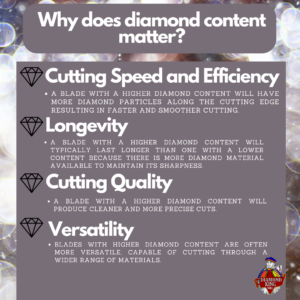

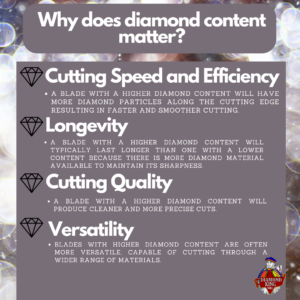

Does Diamond Content Matter in a Diamond Blade?

If you’re in the construction, masonry, or stone-cutting business, you’re likely familiar with the diamond blade. These blades

Best Diamond Blades On The Planet

If you’re in the construction, masonry, or stone-cutting business, you’re likely familiar with the diamond blade. These blades

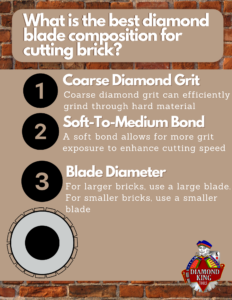

If you’re looking at diamond blades, and you’re not sure which one to get, there are some questions

When you’re working on a project, you want to have the best tools for the job. The best

It’s spooky season, and we’ve got some scary good deals to take advantage of. Here at Diamond King

Diamond King Tools carries some of the most innovative construction products on the market. We also like to

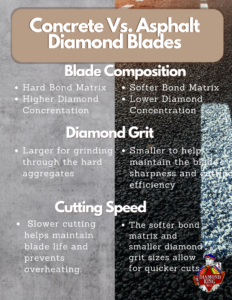

In the realm of construction, precision and efficiency are of utmost importance. Whether it’s cutting through concrete, masonry,

Ductile iron cutting diamond blades are specialized cutting tools designed for cutting through ductile iron, a material known

Will it cut? Diamond king blades cutting random objects

Diamond King core bits for concrete, asphalt, brick block and stone

Will it cut episode 7. will the red devil diamond blade cut an igloo cooler