Asphalt cutting is a crucial task in construction and maintenance projects, ranging from roadwork to driveway repairs. Achieving precise and clean cuts in asphalt requires the right tools and techniques. In today’s post, we’ll be going over some of the best practices for cutting asphalt.

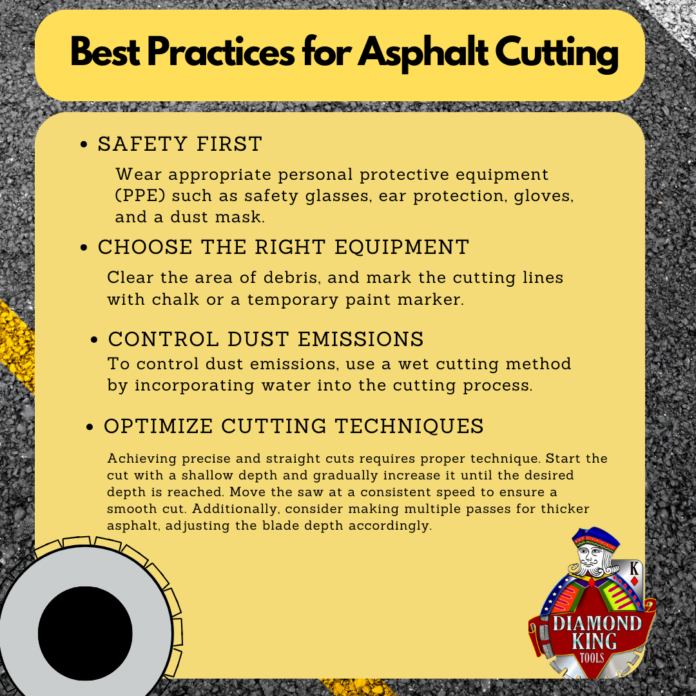

1. Safety First

Before diving into asphalt cutting, prioritize safety. Wear appropriate personal protective equipment (PPE) such as safety glasses, ear protection, gloves, and a dust mask. Make sure the cutting area is clear of obstacles, and establish a safe working zone to prevent accidents.

2. Choose the Right Equipment

Selecting the right cutting equipment is essential for a successful asphalt cutting project. Diamond blade saws are widely regarded as the best choice for cutting asphalt due to their durability and ability to maintain sharpness through abrasive materials. Ensure that the saw is equipped with a water cooling system to control dust and minimize overheating.

3. Inspect and Prepare the Asphalt Surface

Before making any cuts, inspect the asphalt surface for any potential hazards or obstacles. Clear the area of debris, and mark the cutting lines with chalk or a temporary paint marker. This step ensures precision and helps prevent any accidental damage to surrounding structures or utilities.

4. Control Dust Emission

Cutting asphalt generates a significant amount of dust, which can be harmful if inhaled and can reduce visibility on the job site. To control dust emissions, use a wet cutting method by incorporating water into the cutting process. Many asphalt saws come equipped with a water supply system to keep the blade cool and control dust. This not only enhances safety but also improves the efficiency of the cutting process.

5. Optimize Cutting Techniques

Achieving precise and straight cuts requires proper technique. Start the cut with a shallow depth and gradually increase it until the desired depth is reached. Move the saw at a consistent speed to ensure a smooth cut. Additionally, consider making multiple passes for thicker asphalt, adjusting the blade depth accordingly.

6. Regular Maintenance of Equipment

To ensure the longevity and efficiency of your cutting equipment, perform regular maintenance. Keep the saw blade sharp, check for any wear or damage, and lubricate moving parts as needed. Regular maintenance not only extends the life of your equipment but also ensures optimal performance during every cutting operation.

7. Proper Waste Disposal

Once the cutting is complete, proper disposal of asphalt waste is crucial. Collect and dispose of the cut pieces in accordance with local regulations and environmental guidelines. Recycling asphalt is a sustainable option and may be available in your area.