Diamond King At Cape Cod Landscape Show 2020

The Cape Cod Landscape Show is always kind of the kick off for the diamond blade season for

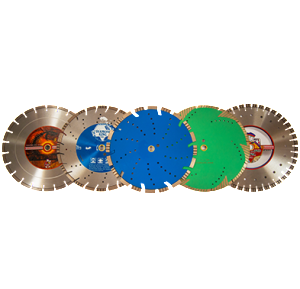

Best Diamond Blades On The Planet

The Cape Cod Landscape Show is always kind of the kick off for the diamond blade season for

Diamond King Tools at World Of Concrete Las Vegas Nevada

For most contractors, diamond blade versatility is a key factor in determining which blade is best for the

Safety is always the top priority in construction. Cutting construction materials can create hazardous dust. Taking all the

Introducing our new After Shock Diamond Blade. The blade is ideal for cutting concrete pavers, stone, natural stone,

This year Diamond King Tools will be exhibiting at the New England Public works expo. This is a

Diamond blades need to be replaced. The frequency of switching out blades depends on a bunch of factors.

Diamond blade segment type plays a huge factor in how the blade performs. Everything from the speed of

Once diamond blades reach 18″, they are usually going on a walk behind saw. These kinds of saws

We hear this all the time. Customers say, “Give me the cheapest diamond blades you have.” Before I