Diamond Blade Knockout Arbors: What They Are and Why They Matter

What Is a Diamond Blade Knockout Arbor? If you have ever installed a diamond blade and noticed a

Best Diamond Blades On The Planet

What Is a Diamond Blade Knockout Arbor? If you have ever installed a diamond blade and noticed a

If you work with brick or own a masonry structure, you have probably heard the term tuckpointing. But

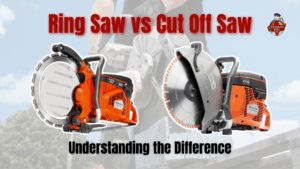

When it comes to concrete and masonry cutting, choosing the right tool can save time, improve cut quality,

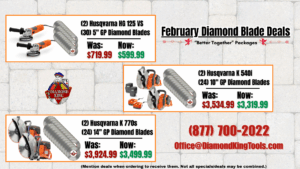

February is all about things that work better together, and at Diamond King Tools, we are leaning into

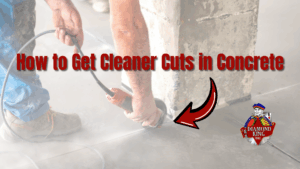

Chipped edges and blowout at the end of a concrete cut can turn an otherwise solid job into

Diamond blades are built tough, but even the best blade can wear out fast if it is used

Kick Off the Year Strong With Diamond King Tools January Deals The new year is the perfect time

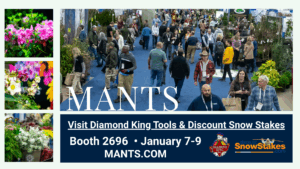

Last week, the Diamond King Tools team had the opportunity to attend the Mid-Atlantic Nursery Trade Show (MANTS)

Diamond King Tools Heads to MANTS 2026 in Baltimore Diamond King Tools is excited to announce that we

Diamond blades are powerful tools designed to cut through concrete, asphalt, stone, brick, and masonry. While they deliver