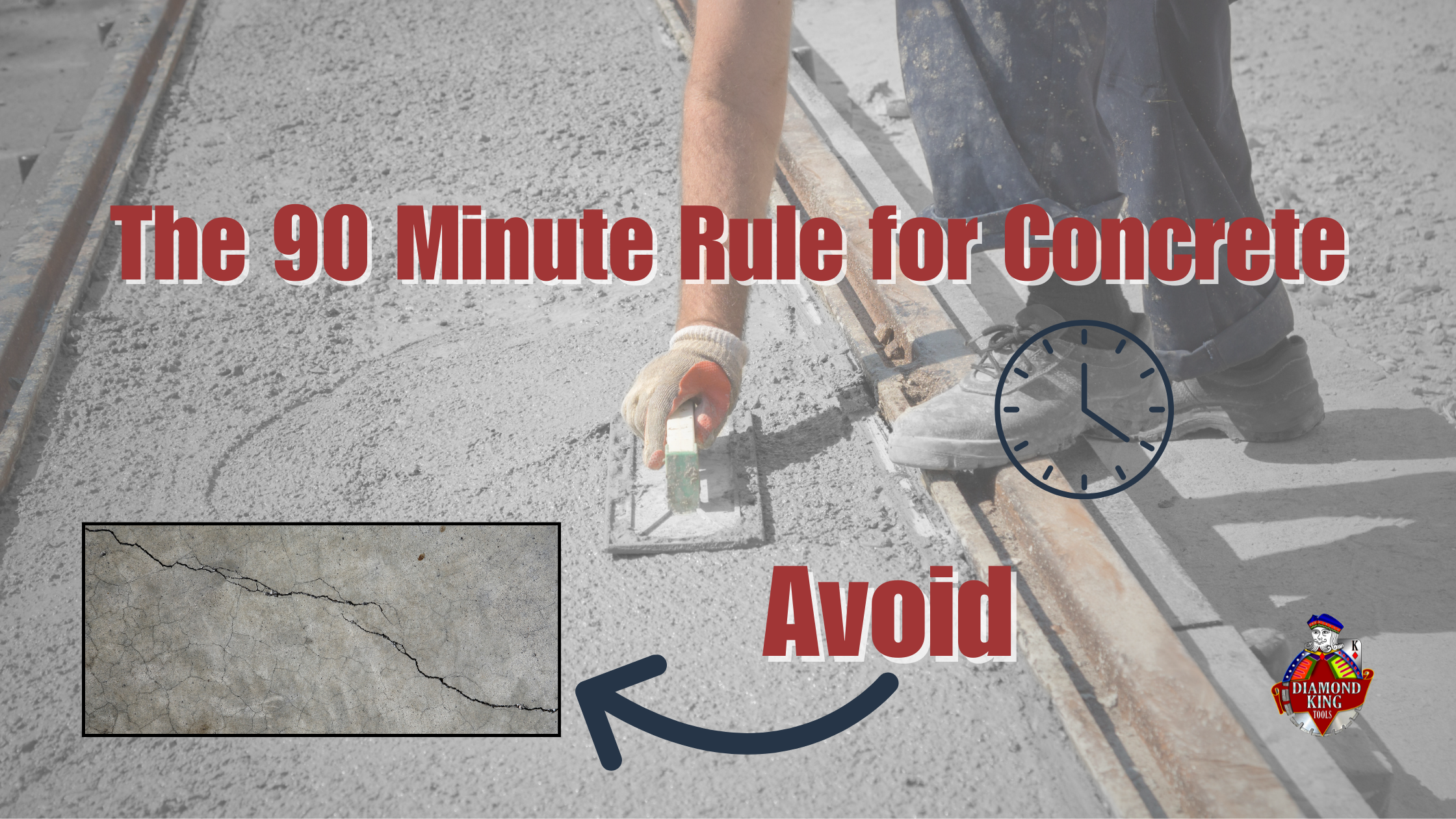

In concrete work, timing is everything. One of the most important timing rules that contractors rely on is the 90 minute rule for concrete. Whether you’re pouring a small pad or working on a large commercial project, sticking to this rule protects the strength, finish, and long-term durability of your slab.

Below is a clear look at what the 90 minute rule means, why it’s so important, and how you can follow it on the job without slowing down your workflow.

What Is the 90 Minute Rule?

The 90 minute rule states that concrete should be discharged from the truck within 90 minutes of the time it is mixed at the plant. After 90 minutes, concrete begins to lose workability and starts setting faster than it should.

This rule is part safety, part quality control. Concrete begins its chemical hydration the moment water meets cement. The longer it sits, the quicker it stiffens, and the harder it becomes to place and finish correctly.

Why the 90 Minute Rule Matters

1. Stronger finished concrete

When concrete sits too long, hydration accelerates. This can lead to cold joints, weak bonding, and reduced compressive strength. Following the 90 minute rule helps ensure the mix sets at the proper rate.

2. Easier placement and finishing

Fresh concrete moves and levels better. If it’s beyond its working window, finishing becomes a fight. You’ll see surface drag, uneven texture, or early crusting.

3. Reduced cracking risk

Over-aged concrete is more likely to crack, scale, or spall as it cures. That means callbacks, repairs, and unnecessary cost.

4. Better control of your schedule

Working within the 90 minute window forces cleaner timing between trucks, pumps, and crews, which leads to smoother jobs.

How to Follow the 90 Minute Rule on the Job

Plan truck timing

Staging trucks is key. Spread deliveries so each load arrives close to when it’s needed, not too early or too late.

Reduce delays

Make sure forms, rebar, tools, and crew are ready before the truck ever shows up. Delays on the ground eat into your 90 minute clock fast.

Use proper access routes

A truck stuck in mud or tight corners wastes precious time. Prep the site so deliveries move smoothly.

Consider admixtures

If you need more workable time, some jobs use approved set-retarders, but this must be coordinated with the batch plant first.

Avoid adding excess water

Never try to “fix” old concrete by adding more water. This weakens the finished product. If the load is out of time, reject it.

Why This Rule Protects Your Reputation

Contractors who follow the 90 minute rule produce stronger, cleaner, longer-lasting slabs. It reduces callbacks, improves customer trust, and cuts down on wasted material and rework.

At Diamond King Tools, we support contractors at every stage of the job. Need the right diamond blade for your relief cuts, expansion joints, or saw lines? We’ve got you covered with blades built for concrete pros.

Call us at (877) 700-2022 or email office@diamondkingtools.com for recommendations.