In the world of cutting tools, the choices can be overwhelming. Whether you’re a professional tradesperson or a DIY enthusiast, selecting the right blade for the job is crucial for efficiency, safety, and achieving precise results. Two common options that often come up in discussions are ductile iron blades and safety blades. We’re going to look into the benefits of ductile iron blades and safety blades.

Ductile Iron Blades:

Ductile iron blades are engineered specifically for cutting through tough materials, and as the name suggests, they excel at slicing through ductile iron. Ductile iron, also known as nodular or spheroidal graphite iron, is a type of iron that exhibits high strength and flexibility. This material is commonly found in pipes, fittings, and other industrial applications.

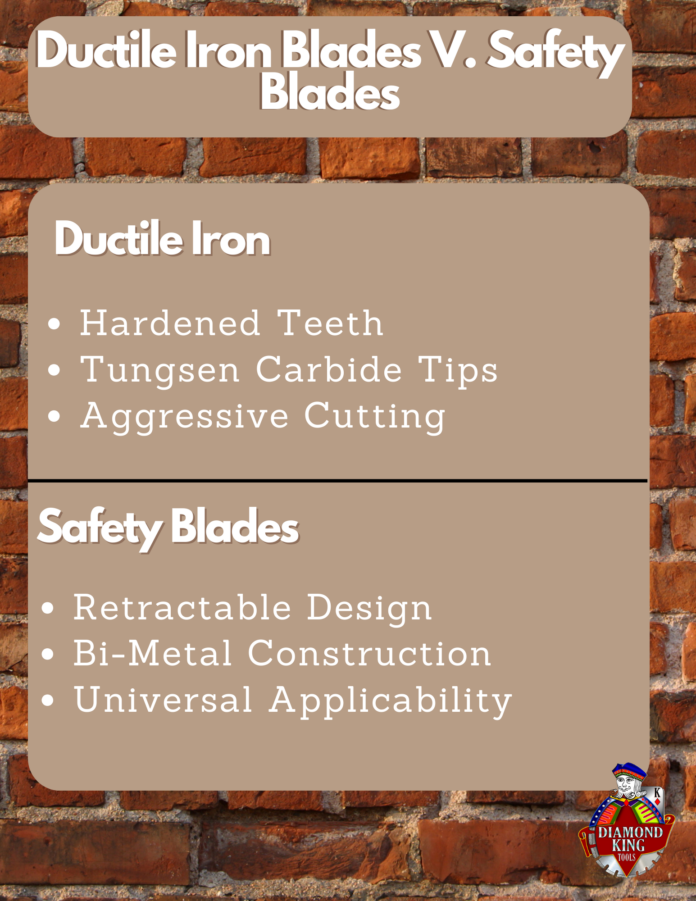

Key characteristics of ductile iron blades include:

- Hardened Teeth: Ductile iron blades typically feature hardened teeth that can withstand the hardness of the material they are cutting. This ensures a longer lifespan for the blade.

- Tungsten Carbide Tips: Many ductile iron blades are equipped with tungsten carbide tips, which enhance the cutting efficiency and durability of the blade.

- Aggressive Cutting: These blades are designed for aggressive cutting, making them suitable for challenging materials. The design of the teeth and the blade’s composition contribute to efficient cutting with minimal effort.

Safety Blades:

On the other hand, safety blades are versatile cutting tools that find application in a variety of materials. Unlike ductile iron blades, safety blades are not specialized for a particular material but are designed to provide a safer cutting experience across different applications.

Key characteristics of safety blades include:

- Retractable Design: Safety blades often feature a retractable design, meaning the blade can be safely tucked away when not in use. This reduces the risk of accidents and injuries during handling.

- Bi-Metal Construction: Many safety blades are constructed with a bi-metal design, combining the benefits of different materials to achieve a balance between flexibility and durability.

- Universal Applicability: Safety blades are suitable for cutting various materials, including cardboard, plastic, and softer metals. Their design makes them a go-to option for general-purpose cutting tasks.

Differences:

- Specialization: The primary difference lies in the specialization of ductile iron blades for cutting through tough, hard materials like ductile iron, whereas safety blades are designed for more general-purpose use.

- Safety Features: While both blades prioritize safety, safety blades often come with additional safety features such as retractable designs and user-friendly handling.

In the quest for the perfect cutting tool, understanding the differences between ductile iron blades and safety blades is crucial. If your cutting needs are specific to tough materials like ductile iron, a ductile iron blade is the ideal choice. On the other hand, if versatility and safety are top priorities, a safety blade might be the better optionThose are some of the benefits of ductile iron blades and safety blades. Ultimately, the right choice depends on the nature of your cutting tasks and your commitment to safety in the workplace or at home.