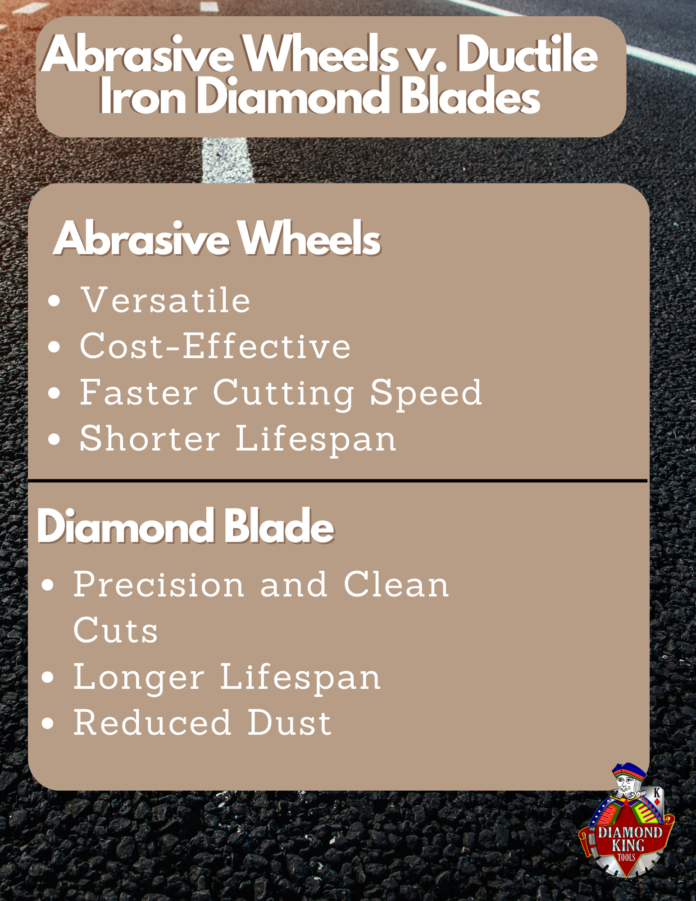

When it comes to cutting materials like ductile iron, you’re faced with the choice of using abrasive wheels or ductile iron diamond blades. Both options have their advantages and drawbacks, and understanding the differences is crucial for making an informed decision. So, which is better: abrasive wheels or ductile iron diamond blades?

When considering abrasive wheels, here are some things to keep in mind:

- Versatility

- Abrasive wheels, such as cutting wheels and grinding discs, are known for their versatility. They can cut through various materials, including metal, concrete, and masonry. This adaptability makes them a popular choice in many construction and fabrication applications.

- Cost-Effective

- Compared to diamond blades, abrasive wheels are often more affordable. This cost-effectiveness can make them an attractive option for those working on a tight budget or involved in one-time projects.

- Faster Cutting Speed

- Abrasive wheels generally provide a faster cutting speed, which can be advantageous when you need to complete a task quickly. The abrasive material grinds through the material, producing minimal resistance.

- Shorter Lifespan

- One drawback of abrasive wheels is their relatively shorter lifespan. They tend to wear down more quickly, especially when cutting hard materials like ductile iron. This leads to frequent wheel replacements, increasing the overall cost in the long run.

If you’re looking at ductile iron diamond blades, here are some things to consider:

- Precision and Clean Cuts

- Diamond blades are known for their ability to produce precise and clean cuts. This is particularly important when working with ductile iron, as it minimizes the need for additional finishing or smoothing of the cut edges.

- Longer Lifespan

- Ductile iron diamond blades have a significantly longer lifespan compared to abrasive wheels. The diamond-tipped segments can withstand the abrasive nature of ductile iron, resulting in fewer blade replacements and reduced downtime.

- Reduced Dust and Debris

- When cutting ductile iron with a diamond blade, there is less dust and debris generated, which can be a significant advantage for worker safety and maintaining a cleaner work environment. Dust control is crucial in many industrial settings to meet safety and environmental regulations.

- Initial Investment

- One of the main drawbacks of ductile iron diamond blades is their higher initial cost compared to abrasive wheels. However, this cost is offset by their longer lifespan and superior performance when cutting ductile iron and other hard materials.