If you’re in the construction, masonry, or stone-cutting business, you’re likely familiar with the diamond blade. These blades are designed to cut through some of the hardest materials, including concrete, asphalt, and natural stone. They do it all with remarkable precision. Why does the diamond content matter? What many people might not realize is that the quality of the diamond blade is tied to its diamond content.

Diamonds are renowned for their exceptional hardness and durability. When used in the construction of diamonds blades, they serve as the cutting edge of the tool. The process of incorporating diamonds into the blades involves binding them to a metallic matrix. This design helps the blade to efficiently grind, cut, and slice through even the toughest materials.

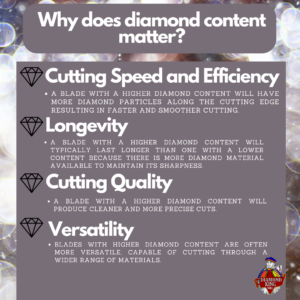

Why Diamond Content Matters:

- Cutting Speed and Efficiency: A blade with higher diamond content will have more diamond particles along the cutting edge, resulting in faster and smoother cutting. Since diamond is the hardest natural substance, a higher diamond content also reduces the need for frequent blade replacements.

- Longevity: Blades with a significant diamond content are more durable and have a longer lifespan. They can endure the wear and tear of tough cutting tasks without wearing out quickly, saving time and money in the long run.

- Cutting Quality: A blade with a higher diamond content will produce cleaner and more precise cuts.

- Versatility: Blades with higher diamond content are more versatile and can handle a broader range of materials and applications. They are suitable for cutting through concrete, asphalt, brick, and natural stone, making them an excellent choice for various construction and masonry projects