If you’re looking at diamond blades, and you’re not sure which one to get, there are some questions you might be asking. One of those could be: what is the different between concrete and diamond blades?

Concrete diamond blades and asphalt diamond blades are designed for cutting different materials and have distinct characteristics to optimize their performance in their respective applications. Here are the key differences between the two:

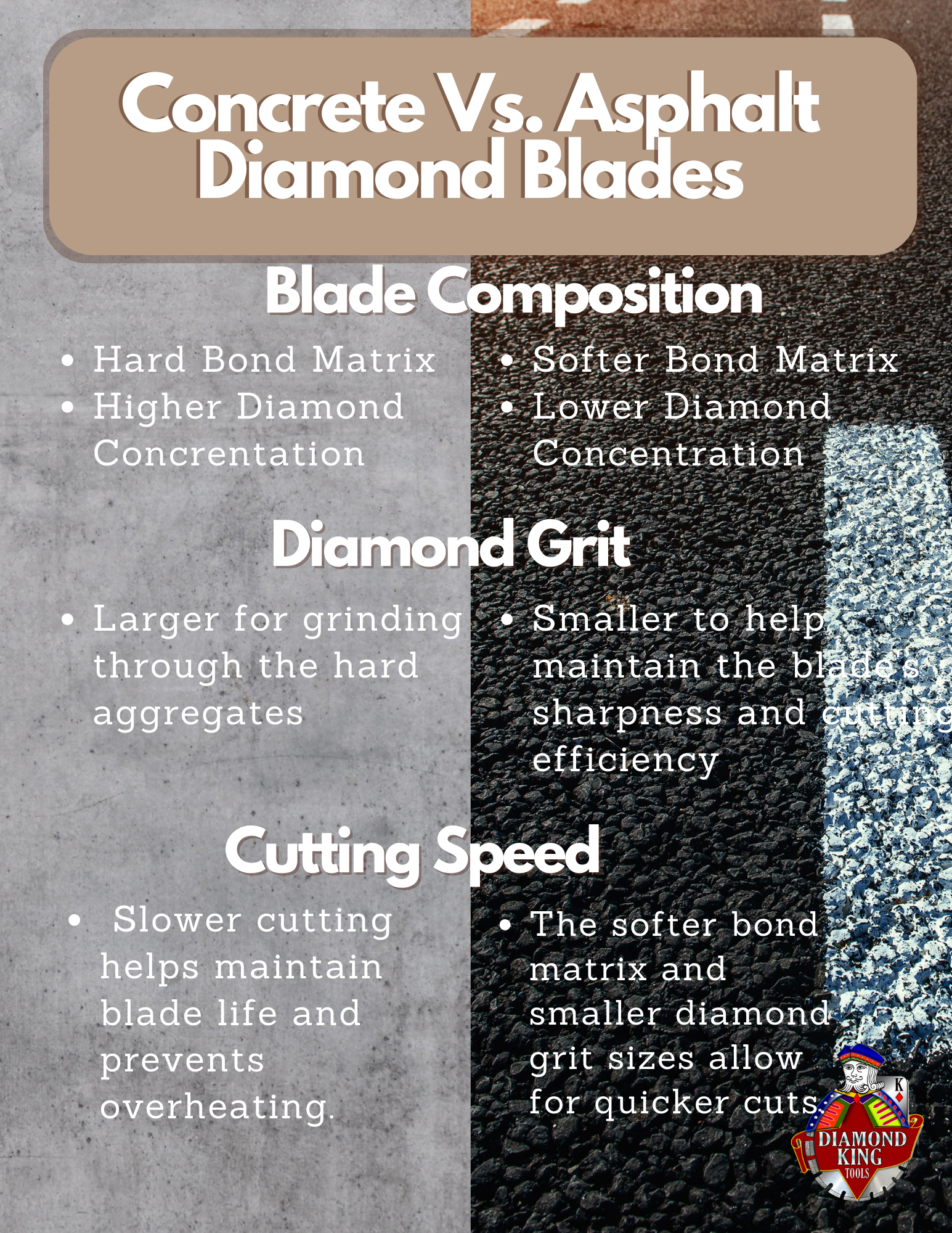

- Blade Composition:

- Concrete Diamond Blade: These blades are typically designed with a harder bond matrix and a higher diamond concentration. The hardness of the bond helps the blade maintain its integrity when cutting through the abrasive nature of concrete.

- Asphalt Diamond Blade: Asphalt blades have a softer bond matrix to allow for better cutting performance in the relatively softer and less abrasive asphalt material. They contain a lower concentration of diamonds.

- Diamond Grit Size:

- Concrete Diamond Blade: These blades often use larger diamond grit sizes, which are more effective for grinding through the hard aggregates and abrasive materials present in concrete.

- Asphalt Diamond Blade: Asphalt blades use smaller diamond grit sizes to help maintain the blade’s sharpness and cutting efficiency when working with softer asphalt.

- Cutting Speed:

- Concrete Diamond Blade: Concrete blades are designed for slower cutting speeds because concrete is a harder and more abrasive material. Slower cutting helps maintain blade life and prevents overheating.

- Asphalt Diamond Blade: Asphalt blades are optimized for faster cutting speeds since asphalt is a softer material. The softer bond matrix and smaller diamond grit sizes allow for quicker cuts.

- Blade Wear:

- Concrete Diamond Blade: When cutting concrete, the blade typically experiences slower wear and has a longer lifespan due to its harder bond and larger diamonds.

- Asphalt Diamond Blade: When cutting asphalt, the blade may wear more quickly because of the softer bond and smaller diamonds. Frequent dressing or sharpening may be required to maintain cutting efficiency.

- Cooling Method:

- Concrete Diamond Blade: Water cooling is often recommended when using concrete diamond blades to dissipate heat and reduce blade wear.

- Asphalt Diamond Blade: While water cooling can also be used with asphalt blades, it is not as critical due to the lower heat generated during cutting.