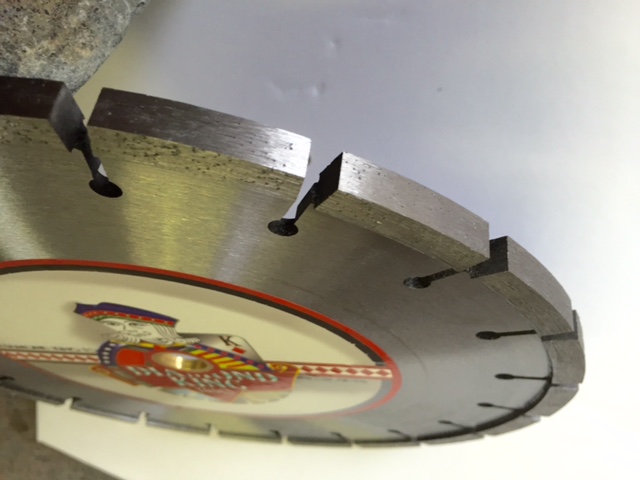

These are a few custom made diamond blades we made for a road cutting customer. The rim thickness is .375 as opposed to standard .160. The customer needs this cutting thickness because they install reflectors in a joint cut into the road. We had never made a diamond blade thick thick previously. It is a BEAST!

We custom make hundreds of diamond blade orders a month for our customers. Everything from rim thickness, segment height and bond can play an important factor in how the diamond blade responds while cutting in certain applications. There are so many different types of saws and saw brands, that in any sort of professional or custom cutting scenario, a diamond blade will have to be specially formulated to perform properly.